Description

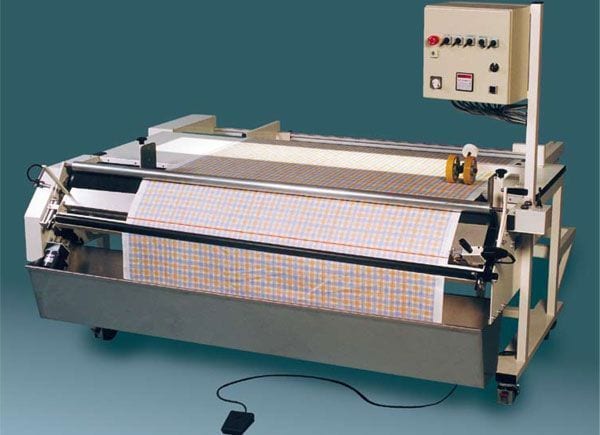

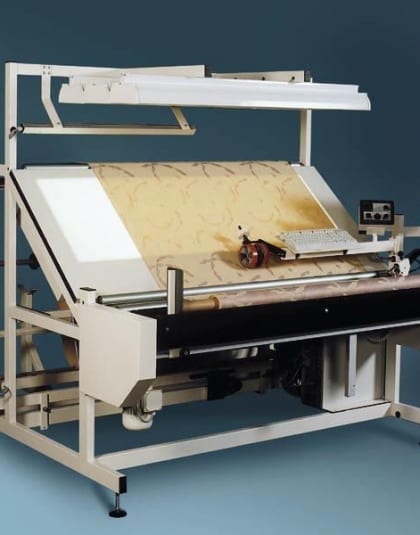

The RUMBA panel cutting machine has been developed for the quick and accurate cutting of cloth rolls into pre-determined lengths, as is necessary for manufacture of curtains and pillows for example. Some important advantages of the panel cutting machine, when comparing it to a traditional cutting table, are: Saving of floorspace, operation by one person, increased productivity, fully programmable length control and optimal inspection facility. The machine has a very stable welded steel construction and is supplied with a cradle with free running anti-static rollers.

For some woven fabrics a rewinding shaft will be useful. The RUMBA panel cutting machine is supplied with an accurate electronic length measuring system and a keyboard with LED display on which the length and number can be easily entered. On request the machine can be supplied with a rewinding facility, with this option it is possible to rewind, check and measure fabric before cutting the roll into pieces. The cut panels will finally be placed in a stainless steel tray or on a folding device. The machine is easy to operate, a roll change can be carried out in a minimum amount of time. The unwinding speed is variable and the acceleration and braking time can be set easily to ensure that the fabric stops at the correct cutting point when using the machine for fabrics with a pattern repeat. A joy stick control and a linelaser are available as an option. The fabric can be cut to length accurately using an electric shear cutter with a clamping device machine, which is located in a tilted angle on a precision guide rail under the driven roller, so the operator has a good view on the cutting line. If you experience problems with fabrics which are out of square a useful option is the adjustable cutter guide rail which can correct up to +/- 5 cm if required.

The RUMBA inspection and panel cutting machine guarantees increased productivity and an improvement in quality. The machine is very comfortable and virtually maintenance free. Several options are available for the machine such as wheels, floor rails, back and overhead lighting, a driven cradle with reverse facility, a nip roller for slippy fabrics, an electric edge control, flat cones for folded fabrics, electric slitters to cut the selvage or to split the fabric and the facility to connect directly to a PC.

FEATURES

- Fabric width up to 350 cm

- Maximum roll diameter 40 cm

- Flexible and modular concept

- Small footprint compared to solution using a cutting table

- One person operation

- Cradle with antistatic rollers

- Inspection table

- Accurate length measurement system with keyboard for programming length and number of panels

- Adjustable cutter rail for correction of out of square panels up to +/- 5 cm

- Line laser for alignment patterns

- Stainless steel container for cut panels

TECHNICAL DATA

- Clothroll width: up to 320 cm

- Diameter of the roll: 40 cm

- Rewinding speed: 0-50 mtr/min

- Voltage: 220/240 V 0,5 Kw

- Net weight: 250-350 kg

- Machine dimensions (L x W x H): fabric_width+70 x 185 x 180 cm

- Power supply 208/230V, 50/60Hz, 1 kW